Following the lead of the New York state government’s commitment to clean energy, the City of New York has passed legislation to do their part to move toward a carbon-neutral future.

The Climate Mobilization Act (1253-2018), a set of bills which was passed overwhelmingly by City Council on April 18, 2019, includes several regulations that affect building owners and developers. The regulations focus on ‘building energy and emissions performance’ and will create a dedicated office within the department of buildings (DOB) whose duties will include, but not be limited to, overseeing the implementation of this legislation within existing buildings, major renovations and new construction alike. Here is an overview of what steps existing building owners (especially of large buildings) in New York City need to take in order to comply with these new mandates.

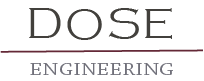

Since buildings are the source of about two-thirds of New York’s carbon emissions, a big part of the legislation is setting new standards for these buildings. The initiatives aim to decrease greenhouse gas emissions from city buildings by 40% (compared to 2005) in the next ten years, and 80% in the next 20 years. Greenhouse gasses include carbon dioxide, methane, nitrous oxide, hydrofluorocarbons, and others.

This ambitious timeline means energy-efficient retrofits will have to occur on a scale that has never been undertaken by an American city. While there are some exceptions, lengthened timelines and reduced requirements for certain building types, for the most part, any building 25,000 square feet or larger must eventually meet new standards. That’s at least 50,000 spaces in New York.

Buildings that are in the top 20% of producing emissions will only have five years to implement changes. Exceptions include electric and steam power generation plants, rent-stabilized apartments (temporarily), places of worship and non-profit hospitals.

Starting in 2024, owners will need to show that the annual emissions of their building did not exceed the limits set in the law. The limits are based on square feet and occupancy, calculating electricity consumed by the building. Limits are calculated as metric tons of carbon dioxide equivalent per square foot (tCO2e/sf). While certain health care and civic facilities will have limits as high as 0.01193 tCO2e/sf, occupancy groups S and U will have the lowest limits to meet, 0.00110 [limits for years 2030-2034]. For the years of 2024-2029, the limits for a commercial building occupancy group B such as office buildings is set at 0.00846 tCO2e/sf.

According to the Energy Information Administration the average office building used 15.9 kilowatt-hours of electricity per square foot in 2012 (EIA ‘table 3: Total electricity consumption and intensities, 2012’). Using the legislation’s calculations for electricity directly consumed from the utility grid, that works out to 0.00459 tCO2e/sf which is less than the maximum limit of 0.00848 tCO2e/sf mandated, so this seems to indicate that at least for now many modern office buildings will already be in line with the new legislation requirements for the years 2024-2029.

The limits are calculated for those using power delivered by the electrical grid. Those that make use of on-site generation, distributed energy or are not on the utility distribution system will have separate rules. And those using steam will have an easier time meeting the requirements, as the calculations for energy consumed are lower than those for electricity.

By December 31, 2024, building owners must show they have undertaken energy conservation measures, including the following:

- Adjusting temperature set points for heat and hot water to reflect appropriate space occupancy and facility requirements;

- Repairing all heating system leaks;

- Maintaining the heating system, including but not limited to ensuring that system component parts are clean and in good operating condition;

- Installing individual temperature controls or insulated radiator enclosures with temperature controls on all radiators;

- Insulating all pipes for heating and/or hot water;

- Insulating the steam system condensate tank or water tank;

- Installing indoor and outdoor heating system sensors and boiler controls to allow for proper set-points;

- Replacing or repairing all steam traps such that all are in working order;

- Installing or upgrading steam system master venting at the ends of mains, large horizontal pipes, and tops of risers, vertical pipes branching off a main;

- Upgrading lighting;

- Weatherizing and air sealing where appropriate, including windows and ductwork, with focus on whole-building insulation;

- Installing timers on exhaust fans;

- Installing radiant barriers behind all radiators;

- Putting solar panels and plants to create green roofs;

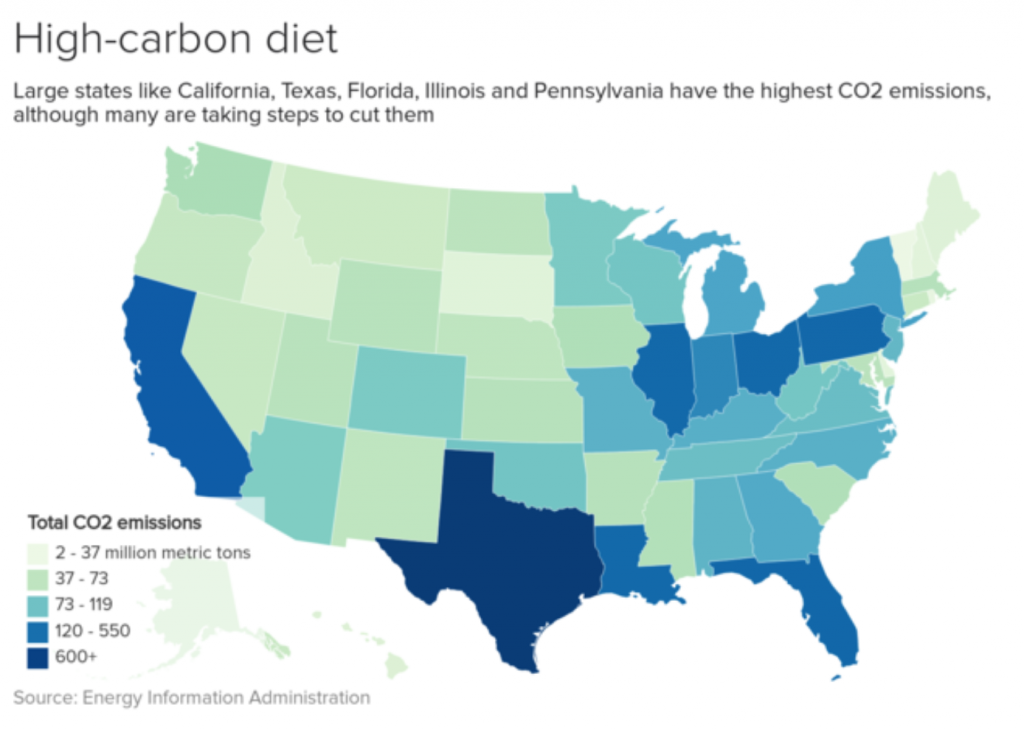

- Use of clean distributed energy resources, including hydropower, solar photovoltaics, geothermal wells or loops, tidal action, waves or water currents, and wind;

- Using energy storage solutions, such as batteries, thermal systems, mechanical systems, compressed air, and superconducting equipment.

The bill provides for the creation of a loan program for businesses to apply to, to undertake these efforts, and new incentive programs are expected to be created.

It will be possible to purchase offsets or renewable energy credits, for up to ten percent of annual emissions, from authorized, local providers.

The new Office of Building Energy and Emissions Performance will oversee the implementation and auditing of the laws and policies in existing buildings and new construction. That department will be issuing the protocols for monitoring energy use by buildings, and creating an online site for building owners to submit their emissions data.

An Advisory Board will include architects, engineers, a building owner or manager, a public utility industry representative, environmental justice and advocacy organization representatives, a business sector representative, residential tenant representatives and a construction trades representative. A separate commission formed in the legislation has until the end of 2022 to create a guide to delineate the responsibilities of the building designer and owners to comply with emissions limits.

The penalties for noncompliance include fees for emissions above set limits, though there may be some leniency if the owner can show due diligence in attempting to comply by investing in energy efficiency measures. Non-reporting could rack up fines of $25,000 a month or more, while those who lie in their reports could face up to $500,000 or imprisonment. So it’s important to plan ahead, and start early to figure out what steps you will take to comply with the new law. As a building owner or developer, consulting with your architect or engineer for building assessment is a good way to start this process and avoid a lot of headaches down the road.

What if you could harness an energy technology that would create not just power but heat for your building, and save you money at the same time?

What if you could harness an energy technology that would create not just power but heat for your building, and save you money at the same time?

Anostere Jean

Anostere Jean