Creating an energy efficient building involves many factors, but an efficient HVAC system is the key. In my last post, I talked about the money that businesses can save by instituting the latest advances in heating, ventilation and air conditioning (HVAC) systems.

Creating an energy efficient building involves many factors, but an efficient HVAC system is the key. In my last post, I talked about the money that businesses can save by instituting the latest advances in heating, ventilation and air conditioning (HVAC) systems.

Here are six such systems/technologies, each of which happens to come with its own acronym!

Variable refrigerant flow (VRF)

These systems use refrigerant fluid rather than of air or water. They are by nature ductless. They can be configured to provide different amounts of refrigerant at different times of day and year, and to different parts of the building (zones). This kind of system is best suited for small areas (1,000SF +/-) with limited space for ducts such as in small offices, shops, dwelling units, computer rooms, hotel/motel rooms, schools, banks etc.

Chilled beam cooling (PCB or ACB)

A passive chilled beam (PCB) is a series of tubes containing chilled water. Warm air in a room rises towards the beam on natural convection currents. The air is then cooled before it descends back towards the floor (and occupants of the room). This is quite energy efficient as no fan is required. A variation that uses more power but provides more cool air is called an active chilled beam (ACB). It pulls the air from the space into a cooling chamber and then forces it back into the room. This is still more efficient than moving air across an entire building.

Adjustable speed/Variable Frequency drives (ASDs/VFDs)

These drives save energy as they are able to lower motor speed and torque as load demand decreases. Some motors even have built-in VFDs in the form of microprocessors. These are also called “electronically commutated motors.”

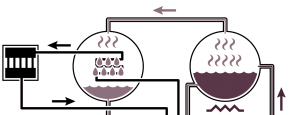

Geothermal heat pumps (GHPs)

These pumps operate a heat exchange with the natural temperature of the ground or water a few feet below the surface depending on site conditions. This is more efficient than exchanging heat with the more volatile temperature of outside air. Ground temperatures in North America are warmer than air in the winter, and cooler in the summer. Moving heat rather than creating it is also more efficient. As a bonus, these pumps are quieter than their counterparts that use air.

Energy Recovery Ventilation (ERV)

These systems work by “double dipping” into the energy that is already being used to exhaust air from a building, transferring heat and moisture from incoming air into the outgoing air. ERV systems are best for buildings located in warmer, more humid climates.

Demand Controlled Ventilation (DCV)

While safety in the form of air quality is of course vital, some systems end up wasting energy by over-ventilating. More modern systems include sensors for carbon dioxide levels, which feed that information to the motors to help determine current environmental ventilation needs.

Electronic expansion valves (EXV)

Here once again is a system that work in the benefit of energy savings. Electronic expansion valves (EXV) is a device that allows for the control of refrigerant flowing through your HVAC equipment, typically the evaporator. As an electronic device, it provides faster, more accurate and steady response to demand of refrigerant flow in the system than the usual thermal expansion valve. This results in the right amount of energy being delivered to the load, hence helping to prevent wasteful usage.

Maintenance

The good news is that these greener HVAC systems usually require less maintenance than older systems. Most of the new systems come with software that tracks equipment use, and will let you know when it’s time for maintenance to keep it at peak efficiency.

Finally, two low-tech maintenance actions that can pay off: Sealing ducts and making sure your building is well insulated are crucial to avoiding the loss of the hot or cold air you’ve worked so hard to bring into the space.