A couple of months ago, New York’s Governor Cuomo issued a statement that the state would go 100% carbon-free energy by 2040.

This statement follows on the heels of approval by the New York Public Service Commission to implement the third stage of its Clean Energy Standard (CES). Both are part of the state’s Reforming the Energy Vision which sets as goals that by 2030 the state will see a 40% reduction in greenhouse gas emissions from 1990 levels, with 70% of electricity coming from renewable sources like wind, solar, and hydro. They also list as a goal a 600 trillion Btu increase in statewide energy efficiency. By 2080, the plan envisions the State will see an 80% reduction in greenhouse gas emissions.

In December 2018, the state’s Power Authority (NYPA) announced that it was investing $250 million in updating its electric grid to be more flexible to incorporate storage of electricity coming from renewable sources. NYPA already produces most of its electricity (70 percent) from hydropower.

In addition, the New York Public Service Commission has set ambitious energy storage goals of 1,500 MW by 2025 and 3,000 MW by 2030. It also sets a target for energy efficiency for the state’s investor-owned utilities to double utility energy efficiency reductions by 2025. These reductions will come in part from retiring any combustion turbine peaking units in New York City and Long Island that were built before 1990.

But what does all this mean for you and your business? For one thing, the state will be making regulatory changes to utility rates and carbon values. Commercial and industry players should expect to see incentives for switching to renewable offerings by utilities, and for using electricity during off-peak times.

Then there are the dozens of state and federal incentives available to businesses looking to transition to clean energy. Through the state’s ground source heat pump rebate program for example, a building can get a rebate of up to $500,000 for installing a pump. Another program will help subsidize the installation of a real-time energy management system.

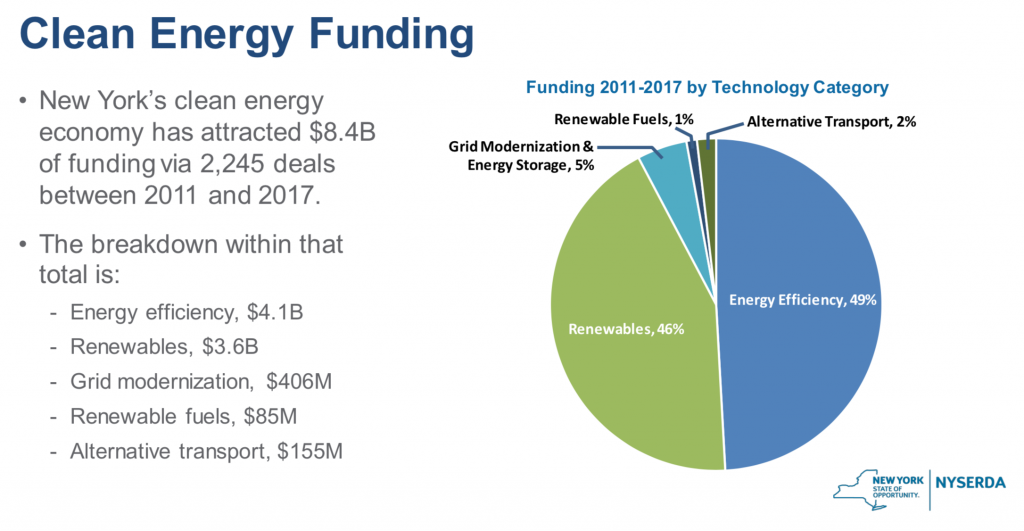

From the 2018 NY Clean Energy Industry Report

Through the NY Green Bank, commercial real estate owners can get financing to purchase and install “energy efficiency and/or renewable energy assets.”

For data centers looking to invest in energy efficiency equipment and productivity improvements, there’s the Industrial and Process Efficiency (IPE) program which offers performance-based incentives to offset costs. The incentives are calculated from the annual kilowatt-hour savings that result from implementing energy efficiency measures.

And it’s not just infrastructure: There’s a program that supports companies in hiring a full-time On-site Energy Manager, and another to encourage On-the-Job Training for Energy Efficiency and Clean Technology.

You can search this database for a comprehensive list for New York and other states.

New York is joining a trend toward 100% renewable energy seen in other states across the nation. Storage target numbers show this commitment. New Jersey wants to see 2,000 MW by 2030; California’s target is 1,300 MW by 2020; and Massachusetts is looking to dramatically increase the state’s existing 200 MWh storage target to 2,000 MW by 2025.

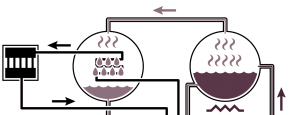

Creating an energy efficient building involves many factors, but an efficient HVAC system is the key. In my

Creating an energy efficient building involves many factors, but an efficient HVAC system is the key. In my